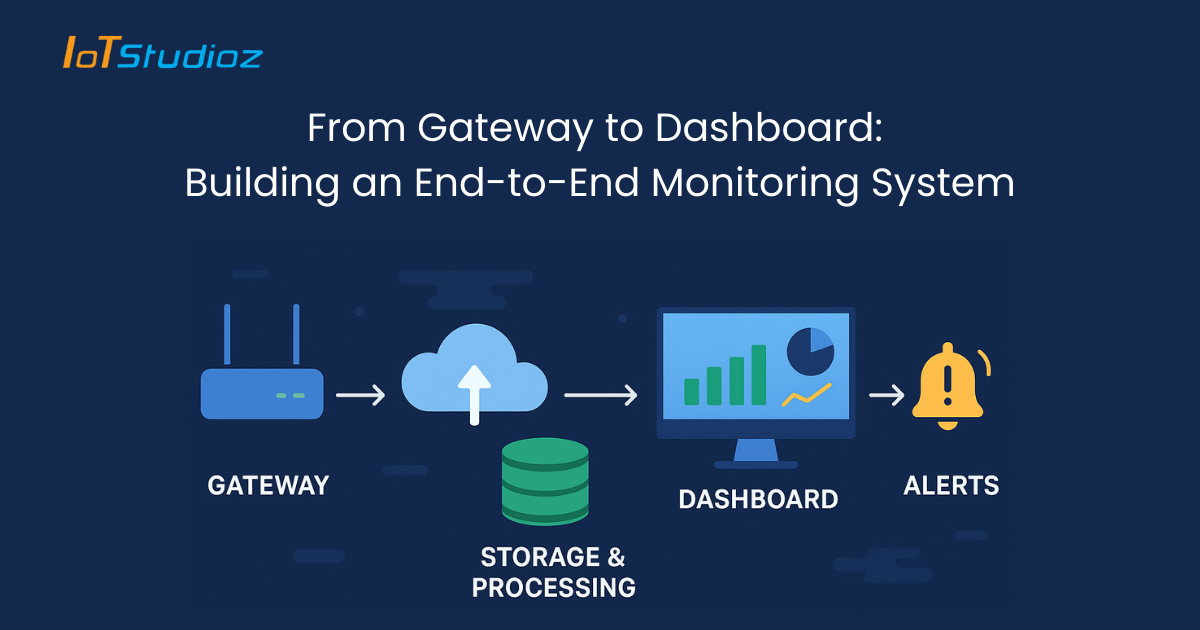

From Gateway to Dashboard: Building an End-to-End Monitoring System

Modern businesses and industries run on data. From factories monitoring machine health to IT teams tracking server performance, real-time visibility is no longer optional; it’s essential. An end-to-end monitoring system