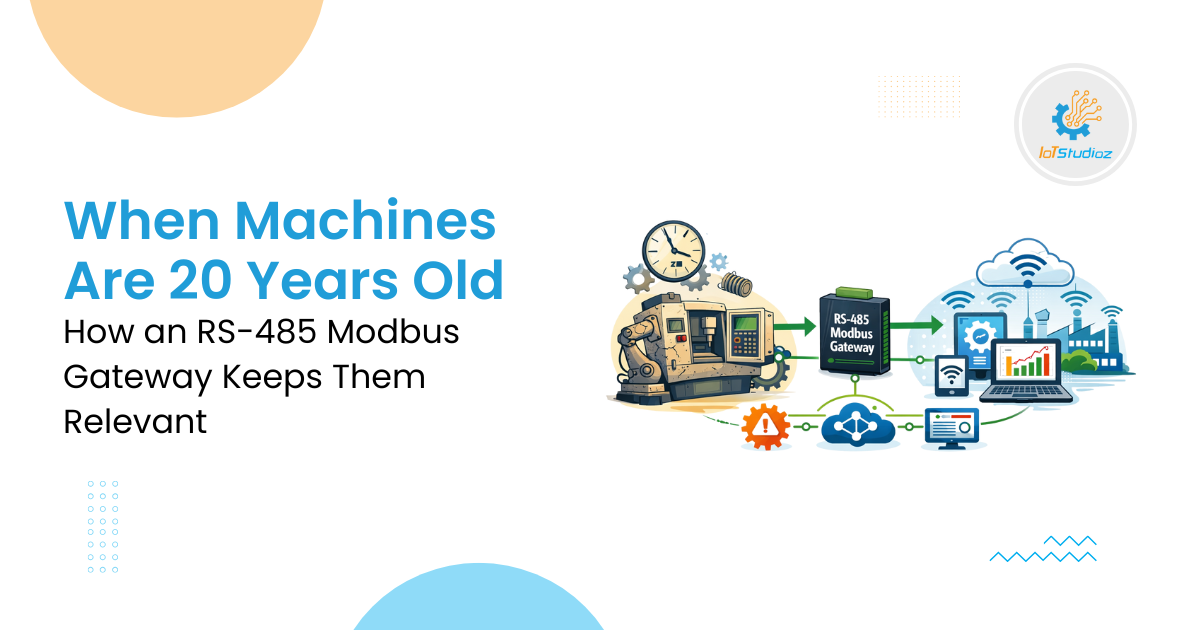

How RS485 Modbus Gateways Enable Real-Time Alarm and Event Monitoring

Modern industrial systems rely on continuous monitoring to maintain operational efficiency and safety. Many facilities still use RS485-connected devices, such as PLCs, sensors, and meters. While these devices communicate effectively