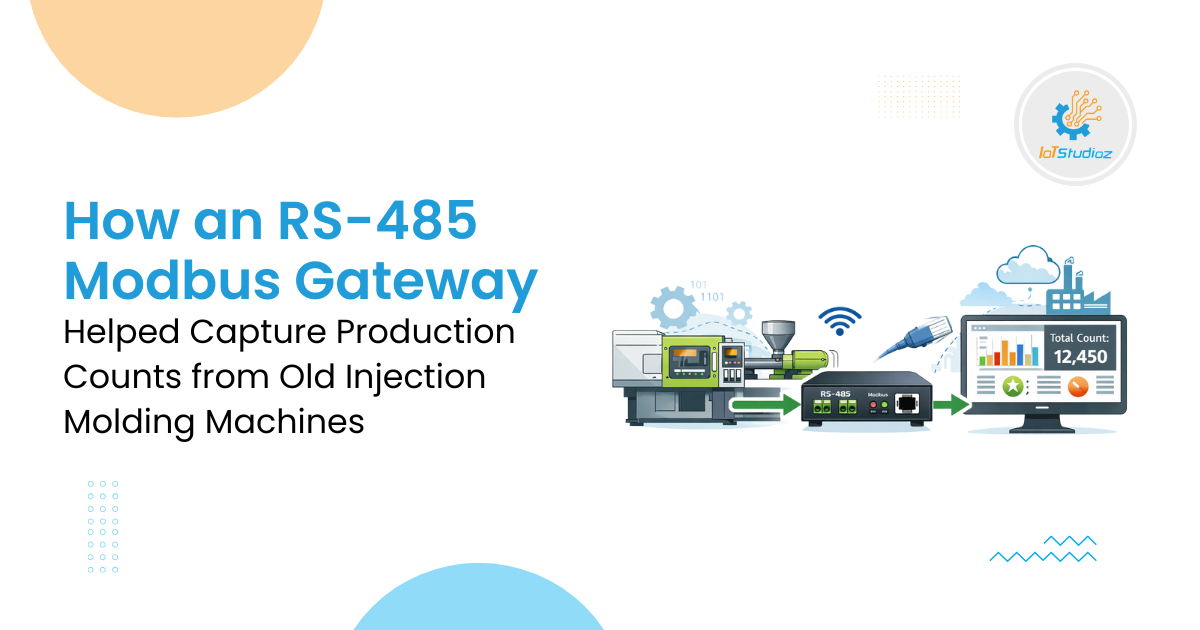

How an RS-485 Modbus Gateway Helped Capture Production Counts from Old Injection Molding Machines

The manufacturing industry faces a growing challenge: capturing accurate production data from legacy machinery. Many factories still operate old injection molding machines that lack modern communication interfaces. Monitoring these machines is essential to measure output, reduce downtime, and improve efficiency. One practical solution is the use of an RS-485 Modbus Gateway. This device allows older machines to communicate production data with modern systems.

This article explains how an RS-485 Modbus Gateway or Modbus RS485 Gateway enables data collection from legacy injection molding machines, explores its benefits, and provides practical implementation examples.

Understanding the Challenge with Old Injection Molding Machines

Injection molding machines are widely used in plastics manufacturing. They shape molten plastic into various forms using molds. Many factories rely on machines installed decades ago.

Challenges include:

- Lack of Digital Interfaces: Older machines often use simple push-button controls or analog signals. They do not support modern industrial communication protocols.

- Manual Data Collection: Operators must record production counts manually, which is time-consuming and prone to errors.

- No Real-Time Monitoring: Without digital communication, production managers cannot track machine output in real time.

- Maintenance Issues: Identifying issues early is difficult without automated alerts from the machine.

A survey conducted by PMMI (The Association for Packaging and Processing Technologies) showed that 65% of manufacturers still use equipment over 10 years old. Most of these machines do not natively support networked data collection.

What is an RS-485 Modbus Gateway?

An RS-485 Modbus Gateway is a device that converts signals from older machines into the Modbus protocol. Modbus is a widely used communication standard in industrial automation. It allows devices to share data over a network.

Key Features of RS-485 Modbus Gateways

- Protocol Conversion: Converts legacy machine signals into Modbus RTU or TCP formats.

- Multi-Device Support: Can connect multiple machines on the same RS-485 network.

- Real-Time Data Transmission: Sends machine production counts, alarms, and status updates to a central system.

- Reliability: RS-485 supports long cable distances (up to 1200 meters) and noise resistance.

The Modbus RS485 Gateway acts as a bridge between old machines and modern software systems like SCADA or MES.

How the Gateway Captures Production Counts

The main goal of using a Modbus RS485 Gateway in injection molding is to capture production counts automatically. Here is how it works:

- Signal Detection: The gateway monitors the machine’s output signals, such as pulse counts or relay signals.

- Data Conversion: It converts these signals into a Modbus-readable format.

- Communication: The gateway sends the data over RS-485 to a PLC or computer.

- Data Logging: The software logs production counts, machine runtime, and other metrics.

Example Scenario

A factory operates ten older injection molding machines. Previously, each machine required an operator to manually record production counts every hour. The factory installed an RS-485 Modbus Gateway on each machine.

Results after implementation:

- Real-time production data was available to the management system.

- Manual data entry errors decreased by 90%.

- Operators saved 2 hours per shift previously spent on reporting.

- Data helped identify machines producing below average output.

Technical Advantages of Using a Modbus RS485 Gateway

Implementing a Modbus RS485 Gateway offers multiple technical benefits for legacy injection molding machines:

1. Compatibility with Old Machines

Older machines often provide simple digital or pulse outputs. The gateway can read these outputs and convert them to Modbus RTU or TCP. This allows seamless integration with modern systems.

2. Reduced Cabling Costs

RS-485 supports long-distance communication over twisted-pair cables. It can connect multiple machines in a daisy-chain setup, reducing the need for complex wiring.

3. Data Accuracy and Reliability

Manual counting often results in errors. Using a gateway ensures accurate capture of production counts, machine status, and faults. RS-485 communication is less prone to electrical noise, improving reliability.

4. Integration with Modern Software

Most modern MES and SCADA systems support Modbus. The gateway enables legacy machines to send production counts directly to these systems, allowing real-time monitoring, reporting, and analytics.

5. Scalability

Adding more machines is straightforward. Additional gateways can be installed on other machines without major rewiring. The system grows as production expands.

Implementation Steps

Implementing an RS-485 Modbus Gateway involves several steps:

- Assess Machine Output Signals: Identify the type of signal each machine provides (digital pulse, relay output, etc.).

- Select the Right Gateway: Ensure the gateway supports the required input type and communication protocol.

- Wiring and Installation: Connect the machine output to the gateway input and link the gateway to the RS-485 network.

- Configure Communication: Set the Modbus address, baud rate, and data format to match the central system.

- Test and Validate: Verify that the production counts are accurately captured and transmitted.

- Integrate with MES or SCADA: Configure the central system to receive and log data from the gateway.

Case Study: A Plastic Manufacturing Plant

A mid-sized plastic manufacturing plant faced challenges tracking production from 15 older injection molding machines. The machines were 15–20 years old and lacked digital interfaces.

Challenges

- Operators manually logged production every hour.

- Data errors caused incorrect inventory reports.

- Plant managers could not monitor machine efficiency in real time.

Solution

The plant installed RS-485 Modbus Gateways on all 15 machines. The gateways read pulse outputs from the machines and converted them to Modbus RTU signals. Data was sent to a central MES system.

Results

- Production counts became fully automated.

- Data accuracy improved by 95%.

- Operators spent 30% less time on reporting.

- Real-time dashboards helped identify underperforming machines.

This example demonstrates the practical benefits of a Modbus RS485 Gateway in improving production visibility.

Cost vs. Benefit Analysis

Upgrading older injection molding machines with an RS-485 Modbus Gateway requires some upfront investment, but the long-term advantages are significant.

Costs to Consider

- Gateway Units: Each device costs between $150 and $400, depending on features and model.

- Cabling: RS-485 twisted-pair cables typically cost $1–$2 per meter.

- Labor: Installation usually takes 2–4 hours per machine.

- Setup and Testing: Configuring Modbus addresses and verifying data transmission adds a small additional cost.

Key Benefits

- Lower Labor Expenses: Automated data collection reduces time spent manually recording production.

- Accurate Production Data: Automated logging eliminates human errors.

- Early Fault Detection: Real-time monitoring helps identify machine issues sooner.

- Improved Production Planning: Reliable data enables better scheduling and resource allocation.

Return on Investment (ROI)

For a facility with 20 machines, the investment can typically be recovered in less than one year. Savings come from reduced labor, fewer reporting errors, and better management of production efficiency.

Common Applications Beyond Injection Molding

While this article focuses on injection molding, RS-485 Modbus Gateways are useful in other industries:

- Packaging Machines – Count items and monitor production rates.

- CNC Machines – Capture operating hours and part counts.

- Conveyor Systems – Monitor throughput and detect stoppages.

- HVAC Systems – Integrate old controllers into building automation.

This flexibility makes the gateway a valuable tool for factories with mixed equipment ages.

Practical Tips for Successful Implementation

- Label All Cables – Avoid confusion in RS-485 networks.

- Check Signal Levels – Ensure machine outputs match gateway input specifications.

- Use Proper Termination – RS-485 lines require resistors at each end to prevent reflections.

- Monitor Performance – Initially, track gateway readings versus manual counts to verify accuracy.

- Plan Network Topology – Daisy-chain RS-485 connections carefully to prevent communication errors.

Conclusion

Capturing production counts from old injection molding machines no longer requires manual effort. An RS-485 Modbus Gateway provides a reliable and cost-effective solution. It converts legacy signals into Modbus communication, allowing real-time data collection and integration with modern MES and SCADA systems.

Factories benefit from:

- Accurate production counts

- Reduced labor costs

- Better machine monitoring

- Improved production planning

By using a Modbus RS485 Gateway, manufacturers can modernize their data collection without replacing expensive equipment. This solution demonstrates that old machines can still provide valuable insights in today’s digital manufacturing environment.

FAQs

1. What is the difference between an RS-485 Modbus Gateway and a standard Modbus device?

An RS-485 Modbus Gateway acts as a bridge between legacy machine signals and a Modbus network. Standard Modbus devices natively communicate using Modbus protocol. The gateway allows older machines without digital communication to integrate into modern systems.

2. Can an RS-485 Modbus Gateway connect multiple machines on the same network?

Yes. RS-485 supports multi-drop connections, allowing several machines to connect in a daisy-chain configuration. Each gateway is assigned a unique Modbus address, enabling the central system to read data from multiple machines over the same network.

3. What types of machine outputs can the gateway read?

The gateway can read various signals from older machines, such as:

- Digital pulses from counters

- Relay contacts or switch outputs

- Analog signals (with compatible gateway models)

These signals are converted into Modbus-readable data.

4. How far can RS-485 communication reach?

RS-485 supports long-distance communication up to 1200 meters (approximately 4,000 feet) using twisted-pair cables. Its differential signaling also provides resistance against electrical noise, making it reliable in industrial environments.

5. Is installation of a Modbus RS485 Gateway complicated?

Installation is relatively simple:

- Connect machine output to the gateway input.

- Connect the gateway to the RS-485 network.

- Configure Modbus settings such as address, baud rate, and parity.

- Test data transmission to the MES or SCADA system.

With proper wiring and configuration, setup usually takes a few hours per machine.