When Machines Are 20 Years Old: How an RS-485 Modbus Gateway Keeps Them Relevant

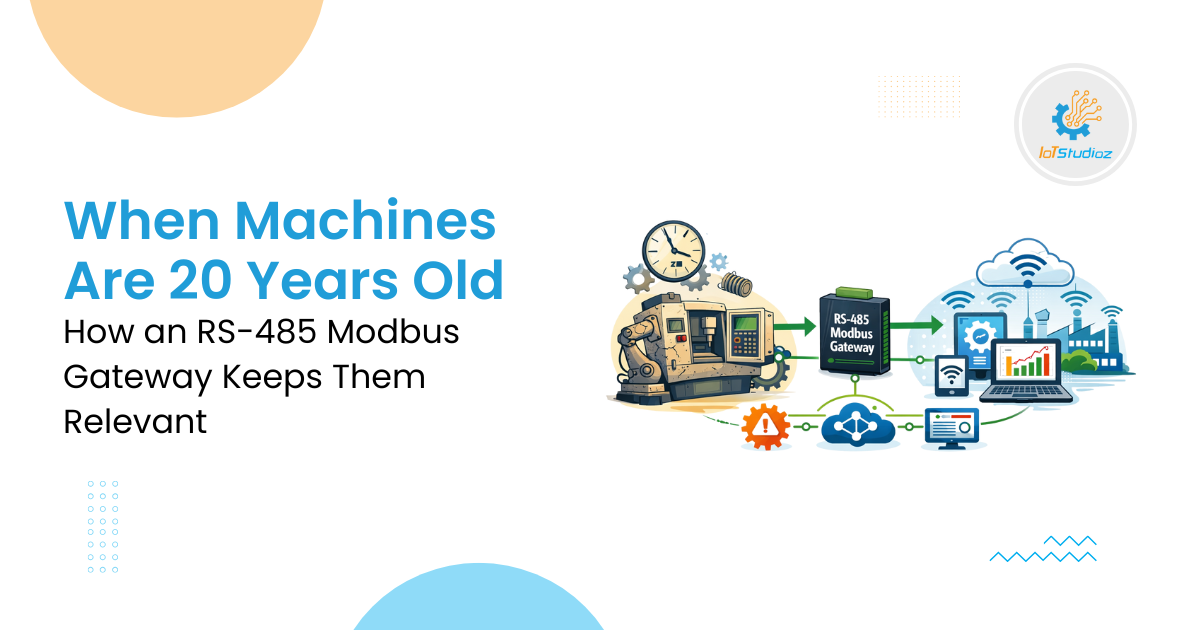

Industrial machines rarely live fast and die young. In sectors such as manufacturing, energy, utilities and process plants, machines are expected to operate for decades if maintained properly. Yet the pace of digital transformation challenges older equipment. How can a 20-year-old machine stay useful in a modern automation environment? The answer often lies in smart communication interfaces like an RS-485 Modbus Gateway or Modbus RS485 Gateway.

This article explains why legacy industrial machines keep running, how modern connectivity standards extend machine lifetimes, and why gateways matter in converting old hardware into modern data participants. We include facts, real industry stats, practical examples, and technical explanations to show how a gateway helps equipment from the past remain useful in today’s systems.

The Reality of Aging Industrial Machines

Industrial machines are built to last. Unlike consumer electronics that depreciate in a few years, machines such as CNC mills, pumps, boilers and SCADA (Supervisory Control and Data Acquisition) systems often operate for 15–30 years. In many cases, uptime requirements, capital constraints, and maintenance budgets encourage firms to keep machines active long past their original commissioning.

Older systems often rely on serial communication standards like RS-485 coupled with the Modbus protocol. These standards emerged in the 1980s and 1990s but remain widely deployed because they are simple and robust.

Why Legacy Machines Persist

- Low replacement cost vs. high uptime risk: Removing a working machine can cost millions when you include lost production time.

- Proven reliability: A decades-old system that works reliably is low risk compared to a new system with unknown issues.

- Existing integration into plant workflows: Plants have invested years in custom programming, operator training, and process stabilization around these machines.

However, the digital age demands that even old machines can share data with modern systems. That is where communication gateways come into play.

The Basics: RS-485 and Modbus Protocol

What Is RS-485?

RS-485 is an electrical standard for serial data transmission. It defines how signals travel over wires but not how the data is structured. Most industrial devices use RS-485 for robust, long-distance communication. It supports multiple devices on a shared bus and can reach distances up to 1,200 meters (about 4,000 feet), even in noisy electrical environments.

What Is Modbus?

Modbus is one of the most widely used communication protocols in industrial automation. First released in 1979, it defines how data messages are formatted between a master (or client) and one or more slaves (servers). Modbus can run over RS-485 (Modbus RTU) or Ethernet (Modbus TCP).

- In a typical Modbus configuration:

- One controller (master/client) initiates data requests.

- Devices (slaves/servers) reply with measured values, status, or control acknowledgements.

- One controller (master/client) initiates data requests.

RS-485 and Modbus work well together. RS-485 handles the physical wire-to-wire communication, while Modbus handles the structure and meaning of data. Together they form a backbone of legacy industrial communications.

Why Legacy Communications Still Matter

Despite modern networks such as Ethernet, fieldbuses and industrial wireless gaining popularity, serial protocols remain critical in many installations.

Market Presence of Legacy Protocols

- In 2023, over 68% of industrial control systems used Modbus RTU or TCP protocols.

- Fieldbus and serial technologies like Modbus still accounted for about 24–28% of industrial network nodes installed.

- Serial-capable devices supporting Modbus are measured in the millions globally.

This data shows that legacy communications still play a significant role even as industrial networks adopt newer standards.

The Problem: Modern Data Requirements vs. Old Machines

Contemporary industrial systems require rich data exchange for functions such as:

- Remote monitoring

- Predictive maintenance

- Cloud integration

- IIoT (Industrial Internet of Things) analytics

- Centralized dashboards

Older equipment with RS-485 and Modbus may not support these features natively. A controller from 2006, for example, might speak Modbus RTU over an RS-485 port and nothing else. It cannot natively communicate over Ethernet or internet protocols like MQTT for cloud systems.

So, how can you integrate legacy machines with modern platforms? That is the job of a gateway.

What Is an RS-485 Modbus Gateway?

An RS-485 Modbus Gateway or Modbus RS485 Gateway is a communication device that translates between RS-485 serial protocols and modern communication standards. It sits between a legacy device and a new network to enable seamless data exchange.

Gateway Functions

- Protocol translation: Converts Modbus RTU messages on RS-485 to modern formats like Modbus TCP/IP, MQTT, OPC UA, or REST APIs.

- Network bridging: Links serial devices with Ethernet, Wi-Fi, or cellular networks.

- Data normalization: Formats old machine signals into usable data points for modern systems.

- Security features: Provides encryption, authentication and filtering where legacy devices cannot.

In short, a gateway acts as a translator and facilitator between old and new equipment.

How Gateways Extend Machine Life

1. Connect Old Devices to New Systems

Without a gateway, an old machine with only RS-485 might communicate with a PLC or HMI locally but cannot send data out to enterprise systems. A gateway converts RS-485 Modbus signals into TCP/IP so that supervisory systems can read machine data and execute commands remotely.

For instance, a 20-year-old boiler’s RS-485 sensor data becomes available in a SCADA dashboard or cloud service via a gateway.

2. Enable Predictive Maintenance

Modern analytics require continuous data streams. Legacy systems often lack this capability. With a gateway, you can collect real-time data for vibration, temperature or pressure and feed it to a maintenance analytics platform.

By analyzing trends, plants can identify failures before they occur. In one real case, connecting old RS-485 devices through an IoT gateway reduced unexpected downtime by up to 60% and cut maintenance labor by up to 40%.

3. Phase in Digital Transformation Gradually

Replacing decades-old machines in one go is costly and disrupts production schedules. Using gateways allows companies to upgrade communications without replacing functional mechanical equipment.

Real-World Gateway Use Cases

Example 1: Manufacturing Plant Upgrade

A metal fabrication plant used several CNC machines built in the early 2000s. Each machine had an RS-485 interface for basic control and monitoring. The plant wanted centralized visibility into cycle times, error codes, and maintenance flags.

By installing Modbus RS485 Gateways, the plant collected data from old devices and sent it over the Ethernet network to a unified dashboard. This resulted in a 15% improvement in throughput due to faster response to stoppages and faults.

Example 2: Energy Management System

A utility company monitored multiple substation devices using RS-485 Modbus RTU. These devices were critical for power distribution but could not communicate over the company’s modern Ethernet infrastructure. A Modbus RS485 Gateway allowed the utility to:

- Send meter data to an enterprise energy management system

- Replace periodic manual data collection

- Support real-time load balancing decisions

Choosing the Right Gateway

When selecting a gateway, engineers should consider:

- Supported protocols: Does it translate to the required modern format (e.g., TCP/IP, MQTT, OPC UA)?

- Processing capacity: Can it handle the number of devices and data points needed?

- Security: Does it provide encryption and authentication?

- Scalability: Can it grow with future requirements?

The global Modbus Gateway market was valued at USD 1.21 billion in 2024 and is expected to grow to about USD 2.19 billion by 2033 at a CAGR of 6.8%.

Technical Challenges and Solutions

Even with a gateway, engineers must address some challenges:

1. Bus Topology and Cable Length

RS-485 networks can support multiple devices but are sensitive to wiring quality. Poor wiring can cause communication errors. Using repeaters or proper termination improves signal integrity.

2. Address Limits

Although a Modbus master can address up to 247 slaves, RS-485 physical limitations typically support fewer devices per segment without repeaters. System design must account for segmentation and addressing.

Conclusion

Machines that are 20 years old still have valuable roles in modern industrial systems. Their control systems and sensors often speak RS-485 and Modbus RTU. A well configured RS-485 Modbus Gateway or Modbus RS485 Gateway bridges the old world and new technologies. It allows legacy equipment to participate in modern data ecosystems, extend asset life, support advanced monitoring, and improve decision-making.

Firms that deploy gateways effectively reduce capital costs, avoid unnecessary machine replacement, and extract more value from long-lasting assets. When a gateway becomes part of the communication path, a machine born in the previous century can still contribute to digital transformation in the next.

FAQs

1. What is the main role of an RS-485 Modbus Gateway?

An RS-485 Modbus Gateway connects legacy devices using Modbus RTU over RS-485 to modern networks. It converts serial data into formats like Modbus TCP or MQTT. This allows old machines to share data with SCADA, cloud, or monitoring systems.

2. Can a Modbus RS485 Gateway work with machines older than 20 years?

Yes, it can. Many machines built 20–30 years ago use RS-485 and Modbus RTU. As long as the device follows Modbus standards, the gateway can communicate with it and forward data to modern systems.

3. Does using a gateway improve machine performance?

A gateway does not change the mechanical performance of a machine. It improves data access, monitoring, and control visibility. Better data often leads to faster decisions, reduced downtime, and improved maintenance planning.

4. Is it cheaper to use a gateway than replacing old machines?

In most cases, yes. Replacing industrial machines can cost hundreds of thousands of dollars. A gateway typically costs a fraction of that amount. Studies show digital retrofitting can reduce upgrade costs by over 50% compared to full equipment replacement.

5. Are RS-485 Modbus Gateways secure for modern networks?

Modern gateways include security features such as user authentication, encrypted communication, and network isolation. These features protect legacy devices that were not designed with cybersecurity in mind.