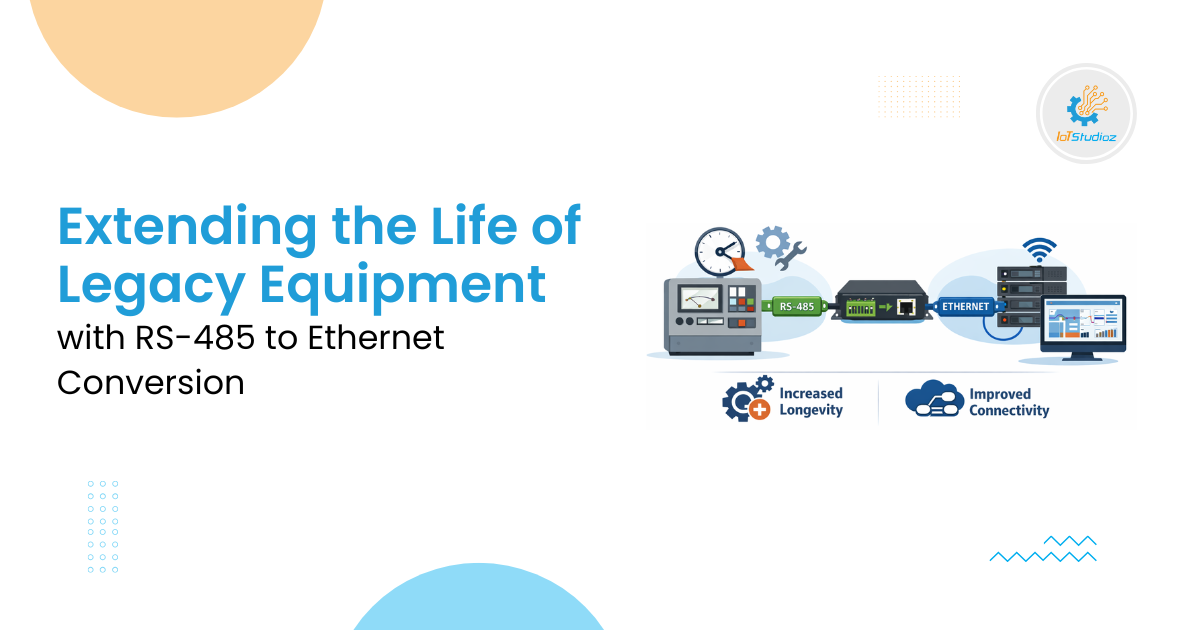

Extending the Life of Legacy Equipment with RS-485 to Ethernet Conversion

Industrial systems often include decades-old devices that still perform reliably. These classic devices communicate using RS-485, a serial standard designed for harsh environments. Yet modern control systems and analytics platforms rely on Ethernet and TCP/IP networks. An RS-485 to Ethernet Converter provides a practical bridge between the old and the new, preserving investments while enabling modern connectivity.

In this article, we explore how RS-485 conversion technology preserves legacy assets, integrates industrial automation systems, and delivers measurable benefits. We aim for an informative, technical perspective with clear facts, examples, and statistics.

What Is RS-485 and Why It Matters

RS-485 is a serial communication standard widely used in industrial control systems. It uses balanced differential signaling over twisted pair cables. This design gives it strong noise immunity and long reach—up to 1,200 m in typical installations. Its multidrop capability connects many devices on a single bus.

This technology remains common in Programmable Logic Controllers (PLCs), sensors, meters, actuators, and industrial drives. It persists because it is robust, inexpensive, and simple to maintain.

However, RS-485 lacks native support for IP-based networks. It cannot directly communicate with modern Ethernet systems. That limitation becomes a major barrier in digital transformation, remote monitoring, and data analytics.

The Need for Conversion: Legacy Equipment in Modern Automation

Industries today face a strong push toward digital transformation, driven by automation and Internet of Things (IoT) requirements. The industrial automation market continues to expand rapidly. Globally, the market is expected to grow from around USD 206 billion in 2024 to nearly USD 379 billion by 2030. Growth reflects investments in automation technologies, modern control systems, and communication networks.

Despite this growth, many physical systems still rely on RS-485 communications. Legacy PLCs, meters, and sensors operate reliably and are not cost-justified for replacement. Replacing these systems purely to gain Ethernet connectivity often entails high capital costs and extended downtime. An RS-485 to Ethernet Converter addresses this without full system replacement.

What Is an RS-485 to Ethernet Converter?

An RS-485 to Ethernet converter is a hardware device that translates serial RS-485 signals into Ethernet (TCP/IP) packets and vice versa. It enables devices that use serial communication to appear on a network like any other Ethernet-connected device.

These converters are also called serial device servers or Modbus gateways when they support protocol translation. They allow existing equipment to communicate over LAN, WAN, or cloud systems without altering the original hardware.

Technical Function

- Signal Reception: The converter receives differential RS-485 signals from a serial device.

- Packet Translation: It encapsulates this data into TCP/IP packets according to defined protocols.

- Network Transmission: Ethernet sends these packets to servers, SCADA systems, or dashboards.

- Reverse Conversion: Commands or data from the network are converted back to RS-485 for devices.

Converters often support standard protocols such as Modbus RTU (on RS-485) to Modbus TCP (on Ethernet).

Key Benefits of RS-485 to Ethernet Conversion

Using an RS-485 to Ethernet converter for industrial automation offers several advantages. These include:

1. Retaining Legacy Assets

Legacy devices aren’t discarded. Converters preserve existing investments and reduce capital expenditure. This strategy is often significantly cheaper than full system upgrades.

2. Remote Control and Monitoring

Ethernet networks enable remote access to data. Sensor readings, machine states, and control commands become available on desktops and mobile dashboards. Real-time data improves decision-making and reduces manual inspections.

3. Integration with Modern Systems

Converters make it possible for RS-485 equipment to communicate with SCADA systems, MES platforms, IoT dashboards, and cloud services. This integration supports analytics, alarms, and performance metrics across the enterprise.

4. Scalability

Ethernet networks support large expansions. Legacy serial buses have limits on distance and device counts, whereas Ethernet can connect hundreds of nodes across sites with minimal rewiring.

5. Improved Data Throughput

Ethernet’s bandwidth exceeds that of serial links. RS-485 may operate at data rates up to several Mbps, but Ethernet routinely provides tens or hundreds of Mbps. Higher speeds support real-time monitoring and larger data flows.

6. Cost Savings and Speed of Deployment

Converters typically offer plug-and-play operation. Most require simple IP configuration and matching of baud rates. There is no need for extensive rewiring or system downtime.

Choosing the Right Converter

Selecting an RS-485 to Ethernet Converter requires an understanding of your application needs. Important factors include:

1. Protocol Support: Ensure compatibility with existing protocols such as Modbus RTU and Modbus TCP.

2. Network Modes: Devices may operate as TCP clients, TCP servers, or support UDP. Choose based on how your network and SCADA systems are structured.

3. Environmental Ratings: Industrial environments require wide operating temperature ranges and rugged construction. Look for devices rated for -40 °C to +85 °C where needed.

4. Isolation and Protection: Galvanic isolation helps prevent ground loops and protects equipment from surges.

Common Use Cases

1. Industrial Automation

Factories often use RS-485 to link PLCs with sensors and actuators. Converters integrate this infrastructure with Ethernet-based controllers and SCADA.

Example: A plant with multiple RS-485 temperature sensors connects each line to an RS-485 to Ethernet converter. All sensors report to a central PLC over Modbus TCP, enabling centralized monitoring and reducing manual checks by an estimated 30 – 40 % in maintenance time.

2. Building Management Systems

HVAC, lighting, and access control devices often use RS-485. Converters enable unified building management dashboards that centralize control and reporting.

3. Energy and Utilities

Smart meters and grid controllers rely on RS-485 for field communications. Ethernet connectivity via converters allows utilities to collect and analyze data from multiple substations efficiently.

4. Transportation and Infrastructure

Railway signaling, traffic control systems, and toll equipment often use legacy protocols. Ethernet integration facilitates remote monitoring and control from centralized operations centers.

5. Smart Cities and IoT

Converters allow legacy devices to feed data into IoT platforms and cloud analytics, enabling trend analysis, predictive maintenance, and operational efficiency.

Performance and Reliability Metrics

Converters are designed for high uptime and stable communication:

- RS-485 supports up to 1,200 m of cable without repeaters.

- Ethernet networks can extend communication virtually without distance limit using routers and switches.

- Industrial converter deployments report uptime rates above 99.9 % in continuous operations.

These figures make converters suitable for mission-critical systems where continuous data flow is essential.

Challenges and Mitigation

Even with strong benefits, converters require careful planning:

1. Latency: Conversion adds slight delays that could impact time-sensitive systems. Select devices with adequate processing performance.

2. Security: Connecting legacy devices to IP networks increases attack surfaces. Use secure protocols and firewalls to protect data.

3. Compatibility: Ensure that baud rates, parity, and protocols match between RS-485 devices and converters.

4. Wiring Quality: Shielded twisted pair cables and proper grounding improve RS-485 communication reliability.

Future Outlook

Industrial automation continues to grow. The market is projected to expand significantly by 2030, driven by digitization and connectivity demands.

Similarly, the market for serial device servers – which includes converters bridging RS-485 to Ethernet – is expected to rise. The 2025 serial device server market is estimated at over USD 305 million, increasing to nearly USD 401 million by 2030, reflecting ongoing demand for legacy integration.

As industries adopt IoT and cloud systems, converters play a critical role. They enable legacy devices to become part of intelligent, connected automation ecosystems without costly replacements.

Conclusion

RS-485 to Ethernet Converter technology provides a cost-effective, reliable path to extend the useful life of legacy industrial equipment. By enabling legacy serial devices to communicate on modern Ethernet networks, these converters support remote monitoring, centralized control, and wider data integration. In the context of a rapidly growing automation market, this approach delivers measurable operational and financial benefits.

Using converters, organizations preserve past investments while unlocking new capabilities in industrial automation. For engineers and planners, they offer a pragmatic bridge between traditional communication standards and the digital demands of today.

FAQs

1. What is the main purpose of an RS-485 to Ethernet Converter?

An RS-485 to Ethernet Converter connects legacy RS-485 devices to modern Ethernet networks. It allows old equipment to communicate with IP-based systems. This helps industries keep existing devices while adopting modern monitoring and control systems.

2. Can an RS-485 to Ethernet converter for industrial automation work with Modbus devices?

Yes, most converters support Modbus RTU over RS-485 and Modbus TCP over Ethernet. This makes them suitable for PLCs, sensors, meters, and drives. Modbus is one of the most common protocols in industrial automation.

3. Does RS-485 to Ethernet conversion affect system performance?

The conversion adds minimal latency. In most industrial applications, this delay is not noticeable. Ethernet provides higher bandwidth, which often improves overall data availability and monitoring speed.

4. Is it safe to connect legacy RS-485 devices to Ethernet networks?

It is safe when proper network security measures are used. Firewalls, VLANs, and access control reduce risks. Many industrial converters also support secure configuration and isolated ports for protection.

5. How long can legacy equipment last when using RS-485 to Ethernet conversion?

Legacy equipment can operate for many additional years if well maintained. Many industrial devices already function reliably for 20–30 years. Ethernet conversion helps extend their useful life without major hardware replacement.